5 key functions of a warehouse management system (WMS)

How can a warehouse management system (WMS) help your warehouse operations? Explore 5 key functions in our guide.

What is a warehouse management system for? It's not a question that can be answered with a phrase – not even a paragraph. This is because a WMS is like a Swiss Army Knife. It combines several key functions into a single tool.

These key functions matter because each one improves one or more of the following: operational visibility, accuracy and productivity. In turn, these are felt by your staff, suppliers and customers.

A WMS can improve the customer service experience, streamline procurement, generate analytics and improve picking accuracy with voice picking solutions.

Not every business needs a warehouse management system – especially in the early days when your inventory is manageable enough to be recorded on a single spreadsheet. But as the SKUs and orders proliferate, a WMS becomes as fundamental as WiFi.

Here, then, are five key functions of a warehouse management system – and why they matter.

1. Customer service experience

WMS providers will often break down for you the functions and benefits of a WMS without mentioning the ultimate aim of it all: keeping the customer satisfied.

A good WMS will do this in two main ways. First, it improves the accuracy of the picking process, keeping picking errors to a bare minimum. If the WMS is integrated with a transport management system, this extends to transport and delivery, too.

Secondly, a good WMS will have a dedicated

B2B customer portalwhere clients can keep track of their orders. This builds trust, boosting customer retention and cutting the number of customer service calls you have to make.

2. Stock visibility

Businesses have a way of suddenly growing in complexity – and this is often seen in warehouse inventory. What began as a manageable spread of items can quickly become unwieldy.

Traditional warehouse management systems aren't hugely useful in this regard. Yes, they provide warehouse staff with a record of everything in stock. But they're hard to update and prone to error. This can hurt the accuracy of your picking, packing and dispatching.

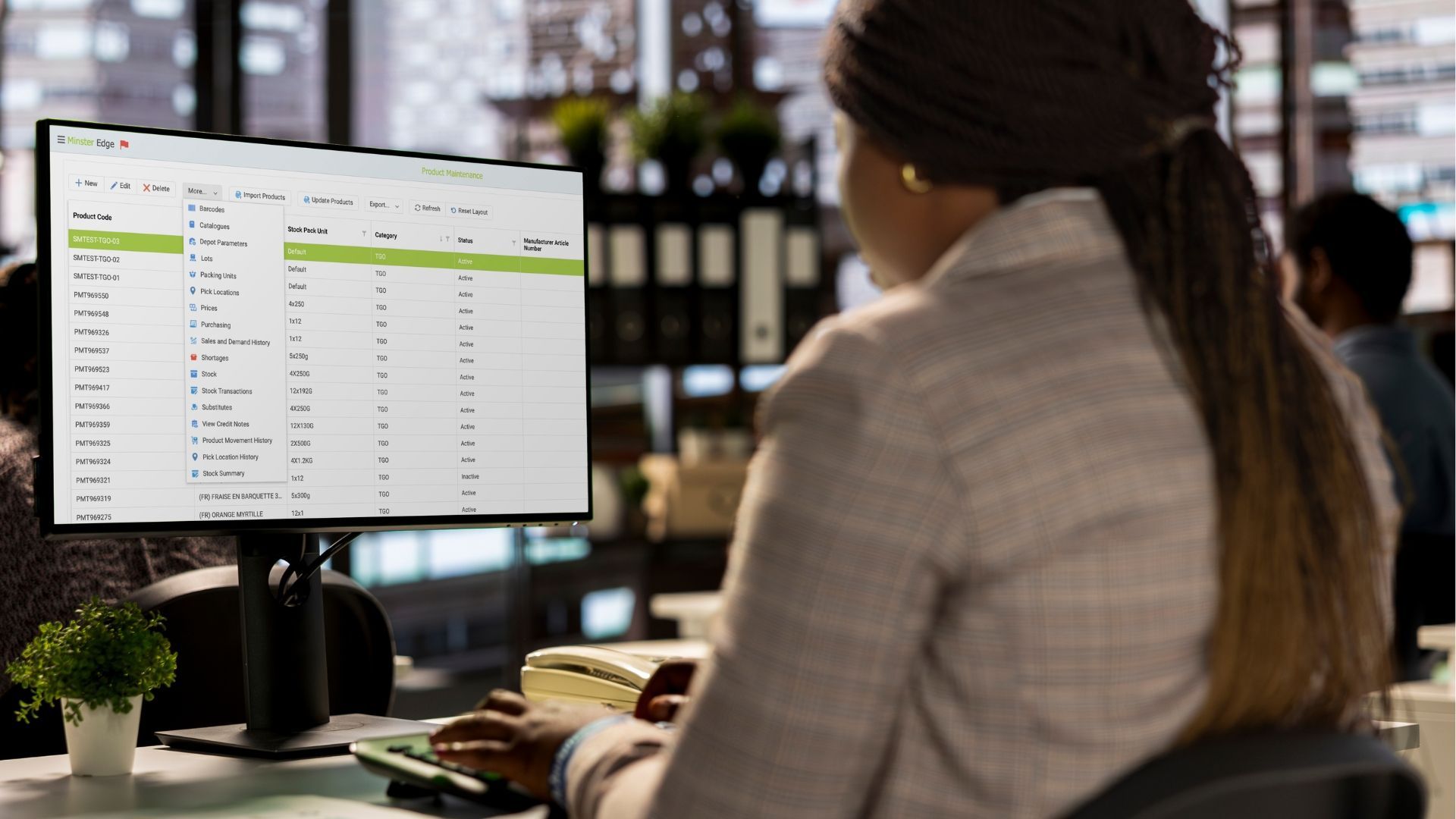

This is where a modern,

cloud-based WMS

comes into its own. Instead of relying on spreadsheets or even pen and paper, you get full visibility into your inventory. This gets updated in real-time and can be accessed at any time in any location.

3. Procurement

Procurement is a tricky aspect of warehouse management – especially at a time when supply chains are more slippery than a basketful of eels.

Whatever software solution you choose, it should serve the procurement process, not work against it. A

cloud-based warehouse

management system

can make a positive difference in this respect.

It allows you, for instance, to maintain optimum stock levels by automatically alerting you when you're in danger of overstocking. It can also automate forecast models to let you know when you need another shipment of X, Y or Z.

All this can be done with just a few clicks of the mouse. It's a far cry from the paper-based systems of old, where reporting, auditing and forecasting were expensive and time-consuming chores.

A similar level of accessibility and speed applies to purchase order processing. A cloud-based WMS lets you automatically generate purchase orders in a jiffy. This is an indispensable weapon in the campaign for efficient procurement.

4. Voice picking

Voice picking has been around for a while – since the early 90s, in fact. It replaces clipboards and other paper records with headphones, a microphone and a barcode scanner.

It essentially works like this. Your warehouse picker is given a verbal command by the WMS through her headphones. She follows the instruction – aisle two, batch three, let's say – and then verbally confirms it.

This process continues until the ordered item is in the right place to be collected and delivered.

By keeping staff's hands free and eyes up, voice picking drastically reduces the likelihood of human error. With our WMS solutions, in fact, it can help you achieve 99.98% picking accuracy.

Accuracy is all very well and good – but the real results will be felt in the spike in customer approval. It's no exaggeration to say that picking accuracy will win you more positive online reviews and more return customers.

5. Reporting and analytics

It's a cliche to say that decision-making should be driven by data, not wishing on a star. But like early birds, bad pennies and stitches in time, it's a cliche for a reason.

Once upon a time, you would have to have a member of staff on hand to crunch the numbers and spit out a strategy – or hire a consultant to do the same. This leveraging of human expertise has its benefits. Speed and cost-effectiveness, however, don't make the list.

But with a cloud-based WMS, all data relating to your stock, orders and fulfilment are in one place and accessible from one dashboard. This means that actionable insights can be generated in the time it takes to make a cup of tea.

In a sense, a WMS's reporting function shows you all the benefits of a WMS in miniature. It's objective. It's fast. It's cost-effective. And it translates into real-world results that keep the customer coming back for more.

Conclusion

Had we but world enough and time, this blog post would cover more key functions of a WMS: integration with transport systems, say, or labour management. But we hope we've made the case for what a WMS can do – and what it can do for your company.

Are you looking for a cloud-based warehouse management system to boost visibility, productivity and accuracy? At Minster WMS, we provide businesses of all shapes and sizes with solutions that work right out of the box and come backed with expert tech support.

Book a demo today

to find out how we can help transform your warehouse operations.