How to improve inventory management: 4 approaches explored

Could your approach to inventory management be fine-tuned? Explore 4 approaches used by businesses today.

Warehouses and distribution centres are the beating heart of eCommerce. If a warehouse is underperforming, the business as a whole suffers.

So far, so obvious. But this basic truth isn't always given the weight it deserves, especially by businesses new to the game.

This is nowhere more clearly evident than in the ways inventory is managed. All too often, we see companies settling for good enough when optimal performance is just around the corner.

There are two main reasons for this. First, old habits die hard. Many businesses simply aren't bold enough to revamp their operations. Better, they reason, to drag around an inefficient apple cart than risk upsetting it.

And secondly, rehauling your warehouse operations takes time and money. The finance team gasps at the initial outlay while management recoils from the prospect of downtime.

These responses are understandable. However, they represent a kind of short-term thinking that prevents warehouses from reaching peak productivity, accuracy and efficiency.

So, how can inventory management be improved? Here are four common approaches – the good, the bad and the very good.

1. Outsourcing inventory management

There's nothing new about outsourcing. But in the 21st century, it's become something of a mantra. Why pour your valuable resources into something that an expert can do for you?

The key advantage is, of course, the fact that you spend less money upfront. Businesses that outsource inventory management spend less on tech and less on labour – at least initially.

And by handing over the reins to a third party, you get to focus on those tasks that are forever sliding down the to-do list – investing in warehouse tech, say, or that new transport fleet forever stuck in the pipeline.

Then there's the question of risk. If you manage your inventory in-house, you take full responsibility for any goofs. But with a third-party provider, the risk is shared.

These benefits are all true – up to a point. But in our minds, handling inventory management in-house with the help of a modern WMS brings more benefits with fewer downsides.

Yes, the initial cost of installing a WMS is an investment. However, the ROI makes up for it – and it means you're actively reaping those rewards, not putting money aside each month for an external service.

And as for risk, well, you have to ask yourself whether the customer cares whose fault it is. If their order is mis-picked because of inventory mismanagement, you're the one getting the bad review – not your warehouse management provider.

Above all, however, the biggest downside of outsourcing is that you relinquish control over your operations. Sure, they should be visible to you online. But you're not making the most of those rich seams of data. This can make your decisions more scattershot and less detail-oriented.

2. Auditing manual processes

Many warehouses have yet to make the jump to a modern WMS for inventory management. They might rely on paper and pen, Excel spreadsheets or a mix of the two. Why? Mainly because an upgrade requires a change of mindset as well as operations.

"If it ain't broke, don't fix it" is good advice up to a point. What it misses, however, is that a functional system isn't necessarily an optimal one.

Yes, things are ticking along OK. But simply auditing your manual processes to see where improvements can be made unlocks far less potential than a full revamp.

Take the question of manual picking. Your methodology is probably sound enough that mistakes are few. But with voice picking, you can achieve an astonishing 99.98% accuracy.

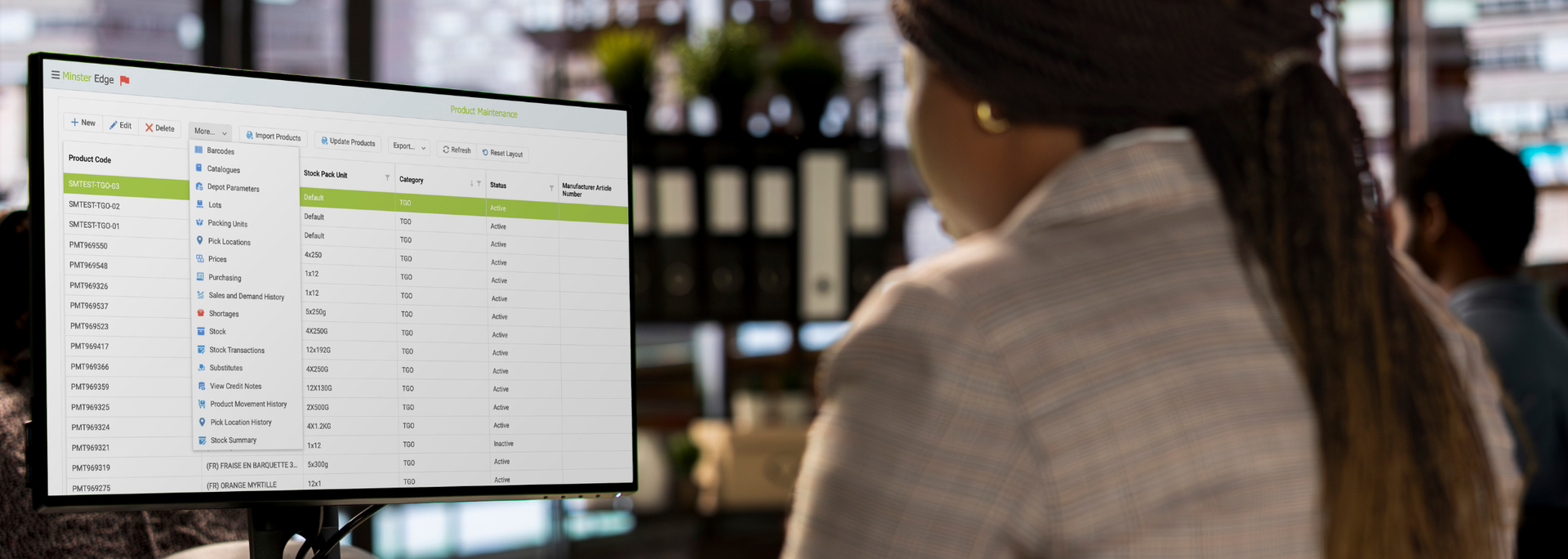

The same goes for stock visibility. Spreadsheets and ledgers are decent records of your inventory. But they don't give you the end-to-end, real-time visibility that a good WMS brings.

3. Upgrading existing software

It's a familiar sight in many businesses. Each department has its own bit of software – multiple bits of software, even. In the case of the warehouse, you might have an inventory management system, a transportation management system and an ERP (enterprise resource planning system).

This patchwork approach to operations has its advantages. Above all, it means that your problems can be dealt with one by one and you're not beholden to a single provider.

As with auditing manual processes, this approach also means you don't have to shell out for a single new piece of software. And some warehouse managers will point to another supposed advantage: sticking with individual pieces of software means no downtime for deployment and training.

This downtime, however, only happens when you work with a subpar provider. A reputable WMS provider will have you up and running quickly and efficiently – in our case, as quickly as 24 hours.

The same goes for training. If your WMS provider leaves you to figure out how the software can help you manage your inventory, you may as well stick with a patchwork approach. But a good provider will hang around to help you keep that disruptive learning curve to a minimum.

Perhaps the biggest reason to avoid this approach is that your different programs don't automatically talk to each other. This can lead to data silos, communication failures and more – all of which are felt first and foremost by your customers.

4. Replacing your system with a cloud-based WMS

In our view, investing in a cloud-based WMS is by far the best way to improve inventory management. By giving you real-time access to all your data, your accuracy will increase and your mistakes will fall through the floor.

A cloud-based WMS brings all your warehouse operations together – and it can be scaled and updated in days, not months.

Plus, if you work with Minster WMS, your shiny new solution comes with top-of-the-range customer support from our team of inventory management IT experts. We're sure that, once you've made the move, you'll wonder how you ever managed without.

Are you looking for a cloud-based inventory management system to unlock efficiencies and help your warehouse reach peak productivity? At Minster WMS, we provide businesses in a range of sectors with highly capable WMS solutions. Book a demo today to find out how we can help you level up your operations.