Warehouse automation: how a WMS can fuel an automated future

Industries across the world are being automated. Find out the role warehouses play in this wave of automation.

The business world is always evolving – and in recent years, "automation" has been one of the words on every business oracle's lips.

Automation, of course, is nothing new. It's at least as old as the water clock. But in the 2020s, automation means digital. It means cloud-based. It means artificial intelligence (AI) and machine learning (ML).

Automation, its proponents argue, can boost efficiency, reduce costs and help businesses stay competitive in a rapidly changing digital landscape. Meanwhile, its critics point to the unavoidable job losses this will entail.

However you look at it, it's undeniable that automation is on the rise. In HR, for instance, automation has increased by almost 600% in the last few years for routine tasks like payroll and onboarding.

Meanwhile, manufacturers continue to deploy robotics on the production line and finance departments continue to automate transactional work – around 80%, according to one estimate.

But how about warehousing? What role do warehouses play in this tide of automation? And how can a warehouse management system (WMS) contribute? Before we answer that question, we need to establish just what we mean by warehouse automation.

What is warehouse automation?

The phrase "warehouse automation" refers to a number of different things – some of which have been around since the early 20th century.

It involves physical systems, such as conveyor belts, forklift trucks and automated guided vehicles (AGVs). It also involves automated storage and retrieval systems (AS/RS). These are large cranes that automatically place and retrieve materials from tall shelving.

These are all at least as old as The Beatles. More recent innovations in warehouse automation include robotics and – more pertinently to our article – software that automates repetitive tasks like picking, packing, sorting and moving goods.

At the time of writing, "warehouse automation" can refer to both eras. It can mean that physical systems become operated by cloud-based software. Or it can refer to the use of software to streamline operations and reduce human error.

It is, as you can see, a broad church – so it's perhaps no surprise just how many core warehouse activities can be automated. These include:

- Receiving and sorting inventory

- Picking and packing orders

- Inventory tracking and management

- Palletising and transportation

- Shipping coordination

Warehouse automation doesn't mean handing the reins over to artificial intelligence. In many cases, human workers remain vital for performing and overseeing automated warehouse operations. The primary purpose is to boost productivity and accuracy, not replace people entirely.

How can a WMS help fuel an automated future?

In today's warehouses, automation can be seen in traditional forms of automation: AS/RS, AGVs, forklift trucks and conveyor belts, to take the most prominent examples.

The difference is that these activities are now orchestrated by a central brain, sometimes known as the "single source of truth". This is a warehouse management system (WMS).

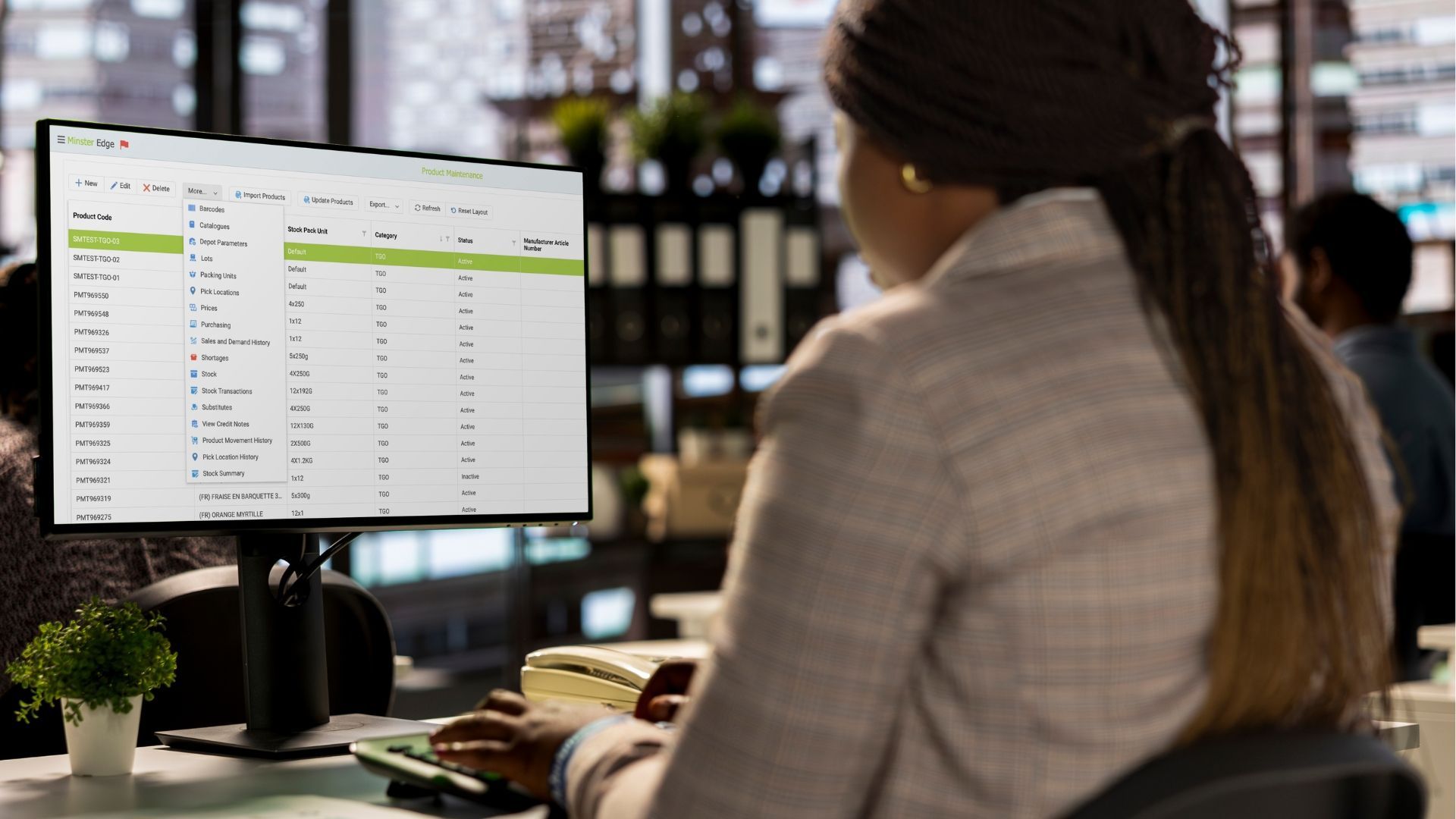

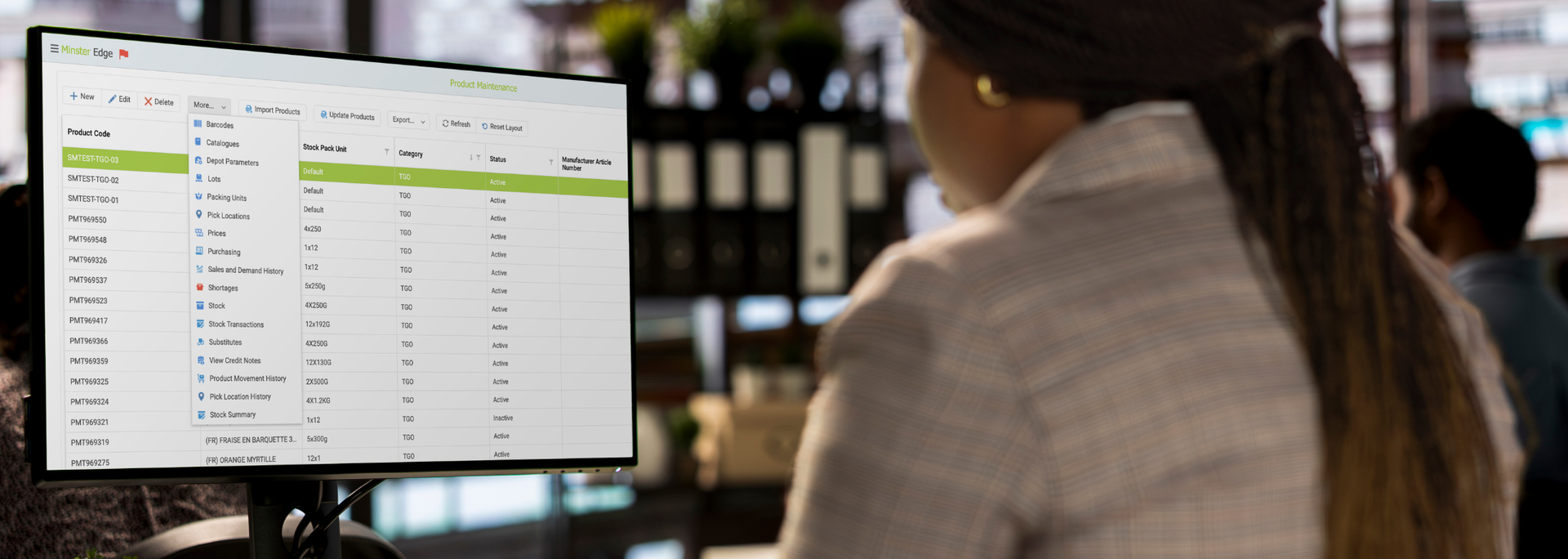

When we talk about a WMS, however, we don't mean a patchwork system made up of ledgers and spreadsheets. We mean a fully centralised piece of software that provides warehouse managers with full visibility into all aspects of their operations, along with real-time analytics and data reports.

The aim is simple: to reduce the need for human intervention in repetitive tasks.

Inventory management

Take the broad question of inventory management. With humans in charge, this is vulnerable to all sorts of errors. Humans are good for many things – but the gathering and recording of precise, real-time data on inventory levels, locations and movement isn't one of them.

By integrating a WMS with barcode scanners, RFID tags and IoT sensors, warehouse managers get end-to-end visibility. This reduces errors in picking, packing and dispatching, ensures accurate and up-to-date information and helps businesses make better decisions.

Data-driven decision-making

That last point is crucial. Data-driven decision-making has long been a dream for businesses of all shapes and sizes. With all your data centralised in one WMS, this dream is close at hand.

With just a few clicks of the mouse, you can generate a report. This report could forecast demand or supply chain disruptions. It could break down the primary reasons for returns. It could identify where mistakes are most often made. All of this can be achieved without paying someone to crunch the numbers for you.

Robotics and voice automation

Warehouse management systems play another role in the automated warehouse. If a warehouse uses robotics, the WMS can send instructions to the robots, telling them what tasks need completing.

If a warehouse employs human pickers, the WMS can send them verbal commands, telling them which items to pick and where to store them, along with the most efficient transport routes.

This use of voice picking can massively improve the accuracy of a warehouse's operations. In the case of our WMS solutions CORE and EDGE, it can help you achieve 99.98% picking accuracy. This is felt most of all by your customers, surpassing their expectations and giving them a reason to come back for more.

What are the benefits of warehouse automation?

In our view, there are five key benefits of warehouse automation:

- Increased efficiency

- Greater accuracy

- Cost-effectiveness

- Better use of space

- Data-driven insights.

Automation can increase your efficiency by speeding up the handling of goods. Crucially, this is tied to an increase in accuracy. Picking errors are slashed while inventory transparency increases.

Automated AS/RS systems have been helping warehouse managers optimise warehouse space for decades. You can give this a further boost by integrating such systems with real-time inventory visibility, real-time tracking and analytics at your fingertips.

Finally, the data at your fingertips can be transformed in minutes into actionable insights. This means you can make better decisions as well as keep a tighter grip on your warehouse inventory and activities.

Are you planning to embrace automation and need an advanced warehouse management system to help you get there? With our fully cloud-based CORE and EDGE solutions, you can be all set for a changing and technology-first future. Book a demo with our UK team today to learn how we can keep you one step ahead.