What is circular logistics?

Circular logistics seeks to make supply chains more environmentally friendly. Find out how in our guide.

In the business world, going round in circles is rarely seen as a good thing. But what if supply chains could form a perfect circle, eliminating waste and keeping resources in use, not landfill?

This vision is known as the "circular economy" – and the practical steps it involves are known as "circular logistics". You could say that the circular economy is a blueprint for a sustainable city, and circular logistics is the roads, vehicles and facilities that make it possible.

It's a concept that's been created in answer to the environmentally wasteful supply chains seen the world over. The transportation of goods too often creates greenhouse gases and landfill. What if it could be extended to offset and cancel out those environmental harms?

Circular logistics is built on so-called "reverse flows". This is because most traditional supply chains progress in one direction only: from supplier to manufacturer to warehouse to customer.

Circular logistics emphasises a further step – from customer back to manufacturer. This could involve the return of waste materials and faulty products to the manufacturer, where they can be recycled, repaired or resold.

The concept has gained traction in recent years as manufacturers strive to cut their emissions. And while we're far from achieving a global circular economy, examples of circular logistics in action can be found across the world.

But before we take a look at these concrete examples – what forms can circular logistics take? And why should your business care?

Examples of circular logistics

Circular logistics is built on the principle that the lifecycle of a product doesn't end when it's shipped to the customer. Instead, reverse logistics are fine-tuned and developed to recapture value and improve a company's carbon footprint.

Without circular logistics, a faulty product or unrecycled return is not just dead value for your company. It's also another broken toy on the piles of landfill that are destroying natural habitats and releasing greenhouse gases into our atmosphere.

Circular logistics can include returns, recycling and refurbishing. Perhaps you sell electronics and want to collect reusable parts. Or perhaps you sell food and drink and want to recycle packaging.

Whatever your precise mission, the principle is clear: less landfill and more value for companies in all sectors and anywhere in the world.

Circular logistics can be self-driven. In many cases, however, it's best achieved in cooperation with others. This is noticeably the case in Denmark, the country where (at the time of writing) circular logistics is most embedded into everyday life.

The fact is that circular logistics can be hard to achieve on your own – especially if you're a small business. It could be, however, that we're entering a period of history when circular logistics develops its own infrastructure, making it easier and more profitable for smaller businesses to take part.

What are the advantages of circular logistics?

In our view, there are three key advantages of circular logistics.

First, it saves money by recapturing value. Components are no longer waste for landfill. They're now recycled or refurbished, enabling businesses to close their margins as they limit their environmental impact.

This is the second key advantage. Sustainability has never been higher on the agenda, even for smaller firms – and a robust reverse logistics policy can do wonders for your carbon footprint.

Finally, circular logistics can help cement your reputation as a thoughtful, environmentally friendly provider, building customer trust and potentially expanding your reach.

Circular logistics may not be the future. But it could play an important role in making our supply chains more sustainable and less wasteful.

Circular logistics in action: five real-life initiatives

1. Apple's Daisy

Daisy is Apple's gesture towards the circular economy. It's a robot that disassembles used iPhones, recovering valuable materials such as gold, copper and rare earths. These are then reused in new products.

Daisy can process up to 200 phones an hour. Impressive!

2. Danish deposit and return system

In Denmark, consumers pay a small deposit on bottles and cans. This deposit is returned to them when they return their bottles and cans to machines in shops.

The returned bottles and cans are then recycled into new packaging. It's a remarkably successful scheme with a return rate of around 93%. At the time of writing, it's one of the most effective schemes of its kind in the world.

3. Gamle Mursten (Old Bricks)

This Danish company upcycles reclaimed bricks from demolitions. These are then reused in new construction projects.

As well as cutting carbon emissions, this recycling project helps architects and designers achieve a unique and historic character through the use of old bricks.

4. The Netherlands

The Netherlands has ambitious goals to achieve a 100% circular economy by 2050. This plan includes circular logistics, promoting designs that can be repaired, establishing repair cafes and encouraging sharing economies.

5. Industrial Symbiosis in Kalundborg, Denmark

Industrial Symbiosis is an eco-industrial park where local companies (both public and private) exchange waste heat, water and industrial byproducts. Participants include power plants, refineries and pharmaceutical companies.

The aim is simple: to reduce waste and recapture value. So far, the scheme has unlocked savings for participants and significantly cut their negative environmental impacts.

What are the challenges of circular logistics?

Circular logistics presents challenges as well as opportunities. Right now, there simply isn't the infrastructure in place to make it a dead cert for businesses – nor is the process clearly regulated.

Perhaps most critically, circular logistics is still a fragmented field. It's likely to become more manageable and more effective as more people get involved and the principles behind circular logistics become embedded in day-to-day operations.

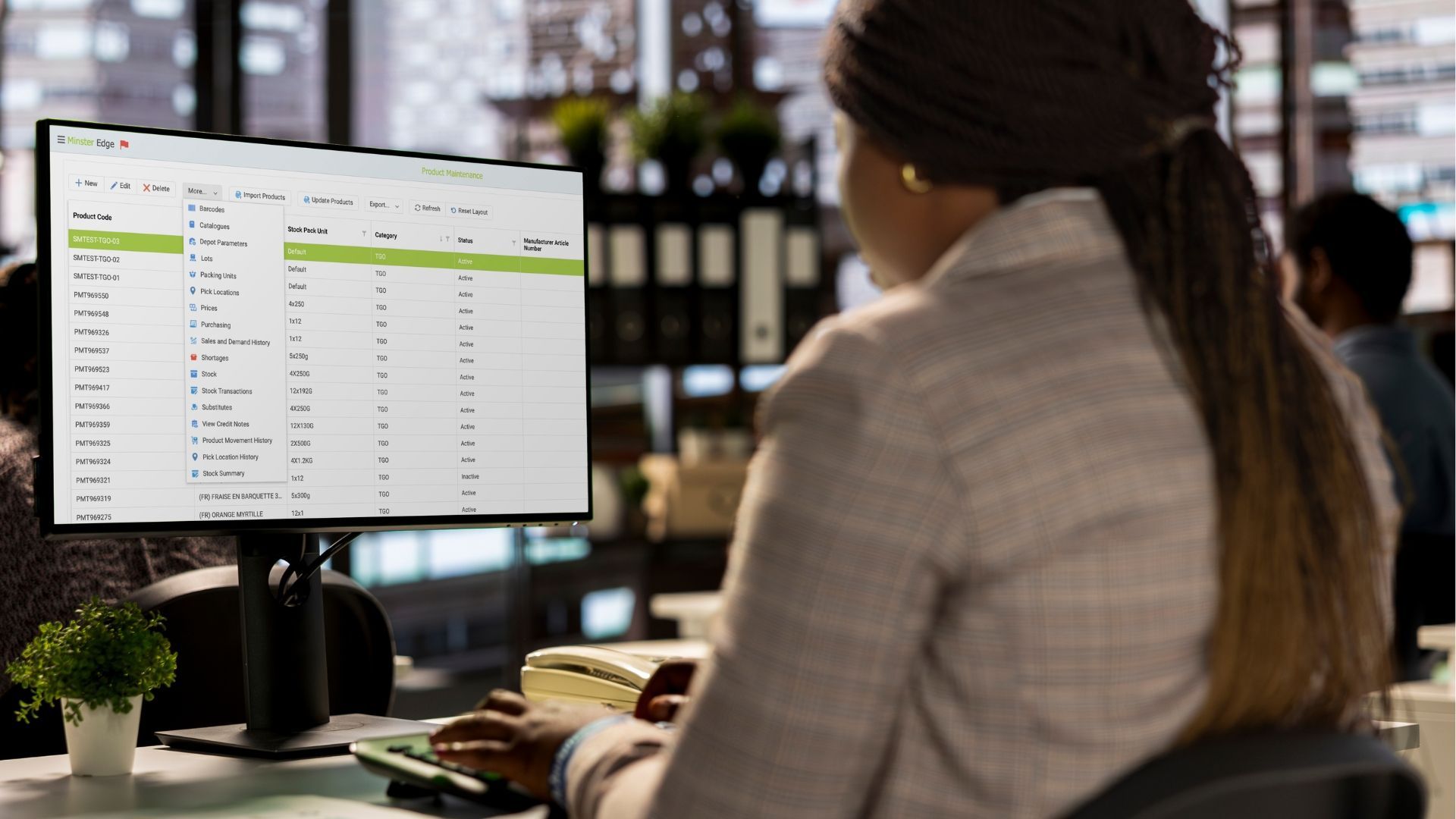

Are you interested in adopting circular logistics and improving your business's carbon footprint? At Minster WMS, we provide cloud-based warehouse management solutions with a robust returns management system built in. Want to see how it can unlock efficiencies and help you achieve your ambition? Book a demo with our experts today.