7 common reverse logistics problems (and how to solve them)

Wasting time and money on returns? Discover how a modern, cloud-based WMS can help you win back your losses.

Reverse logistics is all about recapturing value. Customer doesn't want a product? The last thing you want is for it to go to landfill.

There's the environmental impact, of course. But if an item goes on the scrapheap, it's a straightforward loss.

One loss isn't the end of the world. But if your operations are set up in such a way that returns become commonplace, you'll start to feel the budgetary heat.

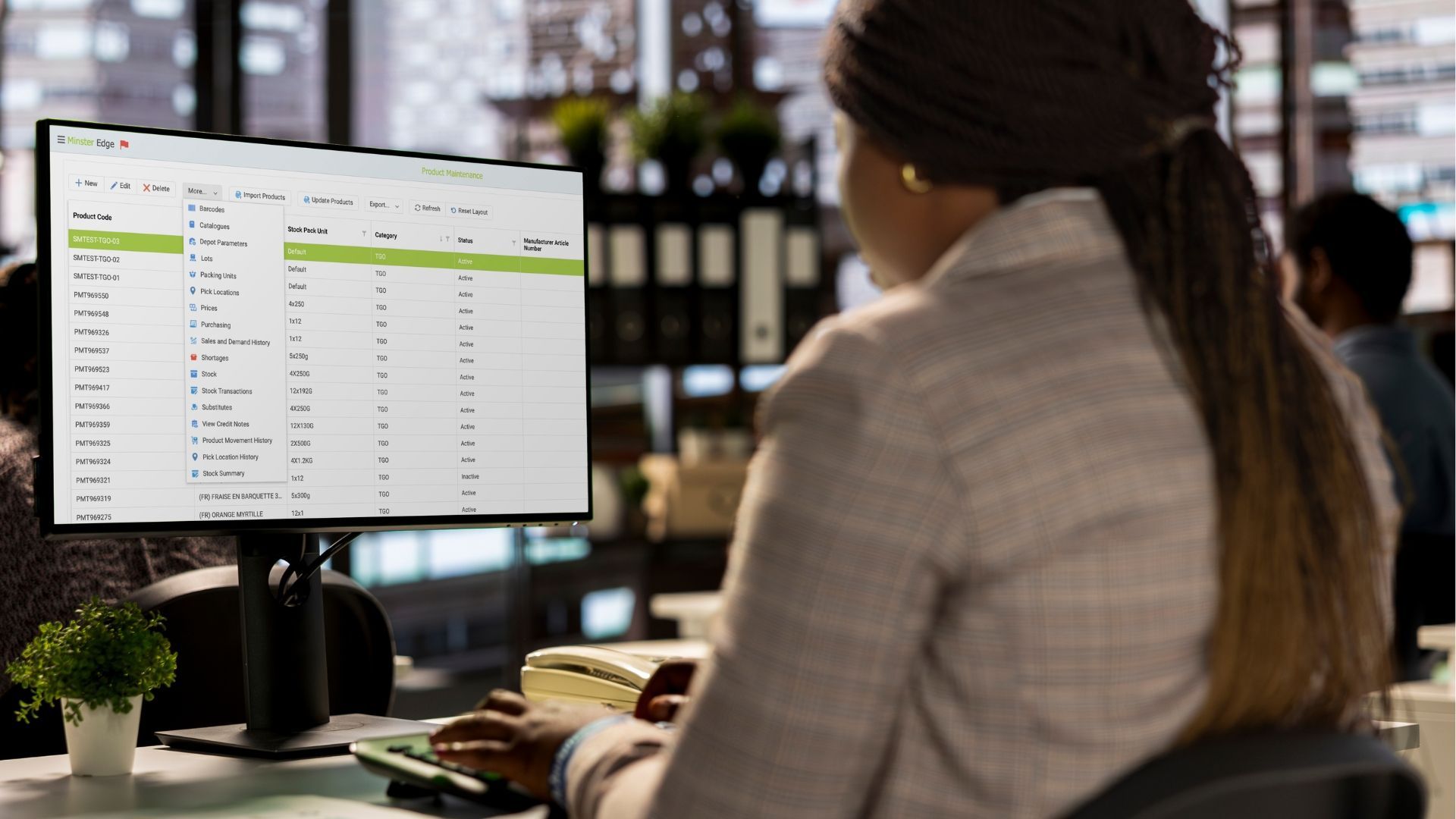

The best way to avoid incurring costs from reverse logistics is to have full visibility over your operations. That means easily accessible data.

Data about the returns process. Data about what you're restocking, what you're recycling and what you're disposing of. Data about deliveries, picking rates, customer feedback and more.

With all this under your nose and at your fingertips, you're in a good position to streamline and optimise your reverse logistics.

But data alone can only do so much. You also want the ability to quickly generate reports based on that data.

All of this can be achieved with an up-to-date, cloud-based WMS. Put simply, there's no common reverse logistics problem that can't be fixed by upgrading your systems.

Here, then, are seven common problems – and how a WMS like our

CORE and

EDGE systems can help.

1. High costs

Managing returns isn't cheap. You have to process the return and inspect the item when it gets back to you. Recycling, disposal and restocking all cost money in different ways. Even if you're just putting the item back on the shelf, it represents a loss.

A good WMS solves this problem by optimising the returns process. Integration with barcode scanners and voice picking mean the item can be sent to its next destination with a minimum of fuss – and no mistakes.

What's more, a modern WMS saves you money overall by increasing the accuracy of your operations. That means money lost to a return is recouped elsewhere.

2. Lack of visibility

Why are your items being returned at all? Sometimes, of course, it's because the customer thought twice and acted on your returns policy. But often, it's because items get lost or damaged in transit.

This can't be avoided entirely. Accidents happen. But by integrating your transport management system with your warehouse management system, you significantly reduce the likelihood of your delivery going awry.

This is partly because a WMS gives you detailed visibility into the returns process. Every aspect of the journey is there at your fingertips and updated in real time.

And because the software is cloud-based, delivery status can be checked at any time from any device in any location.

3. Overcomplicated processes

Reverse logistics is logistically complicated. It requires coordination and communication between couriers, customers and warehouse staff.

If you're working with a legacy IT system, this is doubtless a headache – and a time-consuming one at that.

With a cloud-based WMS, you get all your systems in one place. Essential data can be pulled up in a heartbeat, simplifying processes and ensuring your returned item is restocked, recycled or disposed of efficiently.

4. Unpredictable amounts of returns

If you're doing a good job, the rate of returns will be far more sporadic than the rate of successfully completed orders.

This is a good thing. But it also presents a challenge. It can be difficult to know how many resources to allocate and how to manage inventory when you don't know how many returns you need to process.

A cloud-based WMS can help by providing you with quickly generated reports. With just a few clicks of the mouse, you get actionable data about reverse logistics trends in your company. This means better planning and better customer satisfaction down the line.

5. Storage limitations

Do you lack the capacity to handle returned products? Is it causing operational bottlenecks? The answer is clear: you need more space. But did you know that a cloud-based WMS can help you get there?

This is because a cloud-based WMS is easy to scale. If you're working with Excel spreadsheets or pen and paper, expanding operations will seriously disrupt your day-to-day activities. But with a cloud solution, you can scale quickly and easily.

That means you can deal with your capacity problem without becoming congested. Win-win!

6. Customer satisfaction

Even if it wasn't your fault, no customer wants to spend their time returning a product. Life is tedious enough without having to repackage and return an item.

This means two things. One, you need your returns process to be as painless as possible. And two, you need warehouse processes in place to keep returns to a minimum in the first place.

A high-quality WMS helps you achieve both these things. The end-to-end visibility it gives you into your warehouse means your reverse logistics processes are streamlined. It also means that errors are kept to an absolute bare minimum.

So, if you're worried about losing customers to returns, you should seriously consider upgrading to a good, modern WMS.

7. Data and analytics

Data, they say, makes for good decisions. But not all data is created equal.

Data split between multiple systems and silos doesn't make for good decisions. Nor does data that's been manually entered with mistakes galore.

This is another area where a cloud-based WMS can make a huge difference. By increasing the accuracy of your data, you're in a much better position to put it to work.

Want to know how much value you can recapture from a returned item? Want efficient workflows that tell you quickly where an item should be sent? All these things can be done with just a few mouse clicks – if, that is, you get software that's up to the job.

Want to improve the accuracy of your reverse logistics function and keep customers satisfied? Our WMS solutions come with integrated returns management software that gives you complete visibility and useful data throughout the process. Book a demo today to see how our solutions can work for you.