The role of data analytics in warehouse management

Are your decisions driven by guesswork? Find out how a good WMS can give you the data you need to improve strategic decision-making.

Suhail Doshi, the CEO of Mixpanel, once remarked, "Most of the world will make decisions by either guessing or using their gut. They will be either lucky or wrong."

It's a quote that's highly relevant to the world of warehouse management. Warehouse managers are veteran decision-makers. They have to make decisions about stock levels, picking methods, supply partnerships and much, much more.

All too often, however, these decisions are based on a mixture of guesswork and gut feelings. But as the statistician W. Edwards Deming said, "without data, you're just another person with an opinion".

So, where do you get the data you need to help make decisions that will benefit your warehouse? The answer lies in a cloud-based warehouse management system (WMS).

Not every warehouse has taken the plunge and deployed a WMS. Some still rely on Excel spreadsheets, siloed software and even pen-and-paper records.

These methods are far from useless. But if you want a near-perfect record of everything that goes on in your warehouse – and the ability to turn that raw data into actionable insights – then a WMS is the way to go.

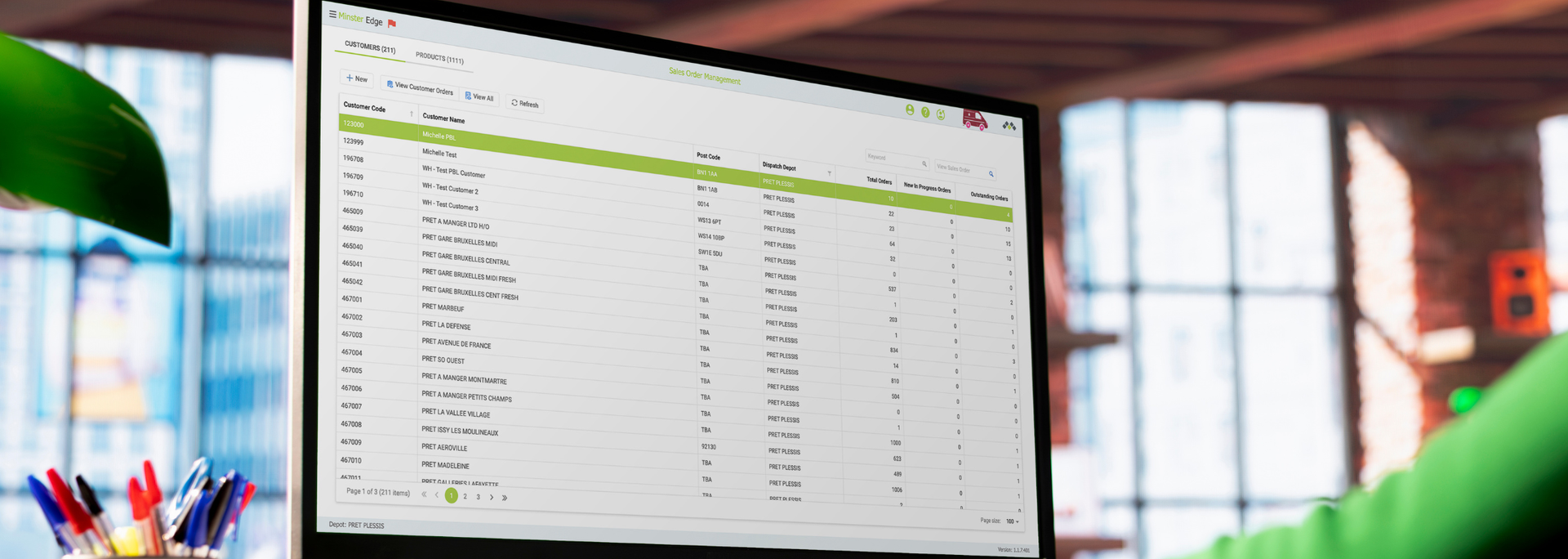

Here at Minster WMS, we provide businesses in a range of sectors with highly capable, cloud-based WMS solutions. There's CORE, our entry-level offering and EDGE, our solution for enterprises.

Both give you end-to-end visibility into all your warehouse ops – and both let you generate reports with just a few clicks of the mouse. This is an invaluable tool when identifying bottlenecks, forecasting demand and streamlining picking, packing and dispatch.

Curious to learn more? Here are five ways data analytics can help transform your warehouse operations.

1. Inventory management

A business is only as good as its inventory – and its inventory is only as good as its warehouse management tools.

Data analytics isn't a crystal ball. But it can help you make data-backed predictions. If market fluctuations and seasonal trends have got you on the back foot, the data reporting function on a cloud-based WMS can make a dramatic difference.

Your data can be put to work in other ways to help with inventory management. You can set a threshold for reordering stock so every time you need to replenish, the decision has been made automatically.

This is a great example of something a WMS can do so well. By automating routine jobs, it reduces the margin of human error – and saves you a tedious task.

And because your data analytics give you a detailed overview of your stock, you have the information you need to avoid stockouts and excess inventory. This optimises your space and lowers your overall costs.

2. Operational efficiency

The world of data can seem abstract – row on row of SKUs, delivery dates and other dry numbers and percentages. But with data analytics, these can be turned into actionable insights to improve the efficiency of your operations.

To take one simple example: not every warehouse has the most efficient picking paths in place. This might only add seconds to the fulfilment process – but over a week, a month or a year, those seconds add up.

Data analytics can identify these inefficiencies. Armed with data, you can make meaningful changes – putting frequently ordered items near each other, for example.

The same goes for staff management. If you can accurately predict peak times, you can accurately allocate staff. That means a healthier profit for you and a more reliable service for your customers.

3. Keeping errors to a bare minimum

Errors in picking, packing and dispatching are down to human error. But rather than blame your staff, it's better to use data analytics functions to identify the causes of those errors.]

This can affect everything from the layout of the warehouse to system integrations and the deployment of new tech. It can even help you book training more effectively.

At the end of the day, people make mistakes, and it's not always easy to know how to change that. With data analytics, your decisions are less of a lottery.

4. Risk management

These days, you'd be forgiven for thinking that supply chain disruptions are the norm, not the exception. Natural disasters, geopolitical events, the COVID-19 pandemic, labour shortages… All create an air of uncertainty that can put your decision-making on a leash.

Data analytics can restore your confidence by anticipating potential supply chain disruptions, demand fluctuations and logistics risks.

It goes without saying that these predictions aren't infallible. Life has a way of throwing you curveballs (remember the pandemic?) However, with data analytics, your predictions are at least based on cold, hard facts – not shapeless fancies.

And because a WMS gives you real-time visibility into your inventory, you're in a far better position to respond proactively when a spanner gets hurled into the works.

5. Cost savings

All of these small benefits add up to one big benefit: they help you save money.

Inventory management, operational efficiency, error reduction, risk management – these all help keep the customer satisfied. But they also help you make savings that can be poured back into branding, R&D or warehouse expansion.

More broadly, a cloud-based WMS can help you cut costs thanks to its easy scalability. Legacy systems make it difficult to branch out into a bigger warehouse or a new facility. With a cloud-based WMS, scaling up can be done in a jiffy.

And if you work with Minster WMS, you'll get best-in-class technical support around the clock. Where other companies route your enquiry to a call centre, we connect you to real experts based here in the UK.

This means you get to troubleshoot in days, not weeks, avoiding the costly disruptions that poor customer service can create.

Looking for a highly capable cloud-based WMS? Let us show you how our WMS solutions can make your data work harder. Book a demo today to get started.